Equipment availability: Q4 2016

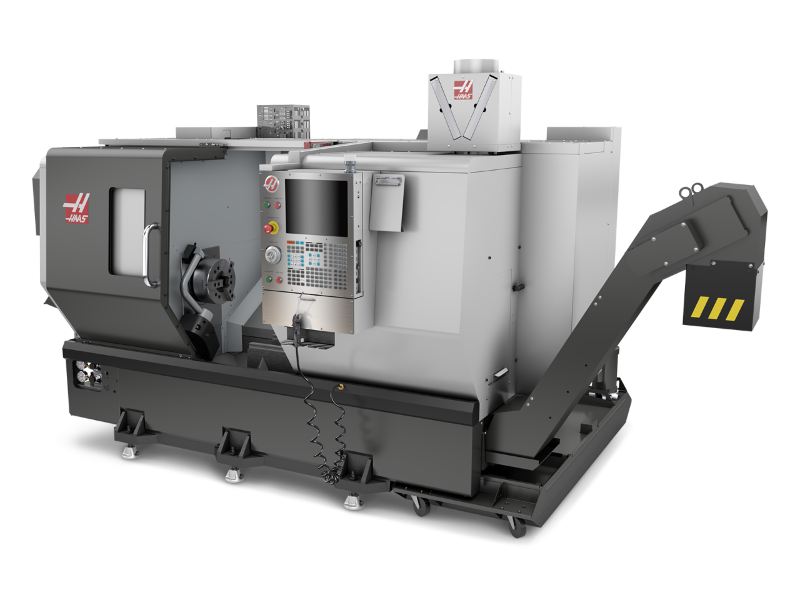

ST Series

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability — and they do!

The ST-20 has a small footprint, yet provides a generous work envelope. This machine offers the best performance for the money – the best value – in its class.

- Small footprint

- Generous work envelope

- Ideal for high-volume, high-production environments

- Made in the USA

For production work, this machine is outfitted with a bar feeder and magazine. This allows repetitive tasks to continue with minimal operator input.

About Machine Shops

Our Machine Shop is a set of buildings with multiple machine tools/work centers, various other equipment and skilled labor to manufacture and/or repair parts. The production can consist of cutting, shaping, drilling, finishing, etc. We also function as a Job Shop by handling job production as a custom/bespoke or semi-custom/bespoke manufacturing process. Some manufactured parts are manually machined while others are more automated. Automation starts with computer numerical control (CNC) machines and leads to computer-integrated manufacturing where production and production design are integrated into CAD/CAM. [1] [2]

About Lathes

A lathe is a machine tool which rotates the workpiece on its axis to perform various operations such as cutting, sanding, knurling, drilling, or deformation with tools that are applied to the workpiece to create an object which has symmetry about an axis of rotation. Metalworking lathes are used to produce most solids of revolution, plane surfaces and screw threads or helices. The material can be held in place by either one or two centers, at least one of which can be moved horizontally to accommodate varying material lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck or collet, or to a faceplate, using clamps or dogs.

Metal is removed from the workpiece using a hardened cutting tool, which is usually fixed to a solid movable mounting, either a tool-post or a turret, which is then moved against the workpiece using hand-wheels and/or computer controlled motors. These (cutting) tools come in a wide range of sizes and shapes depending upon their application. Some common styles are diamond, round, square and triangular. [1]

Leave a Reply