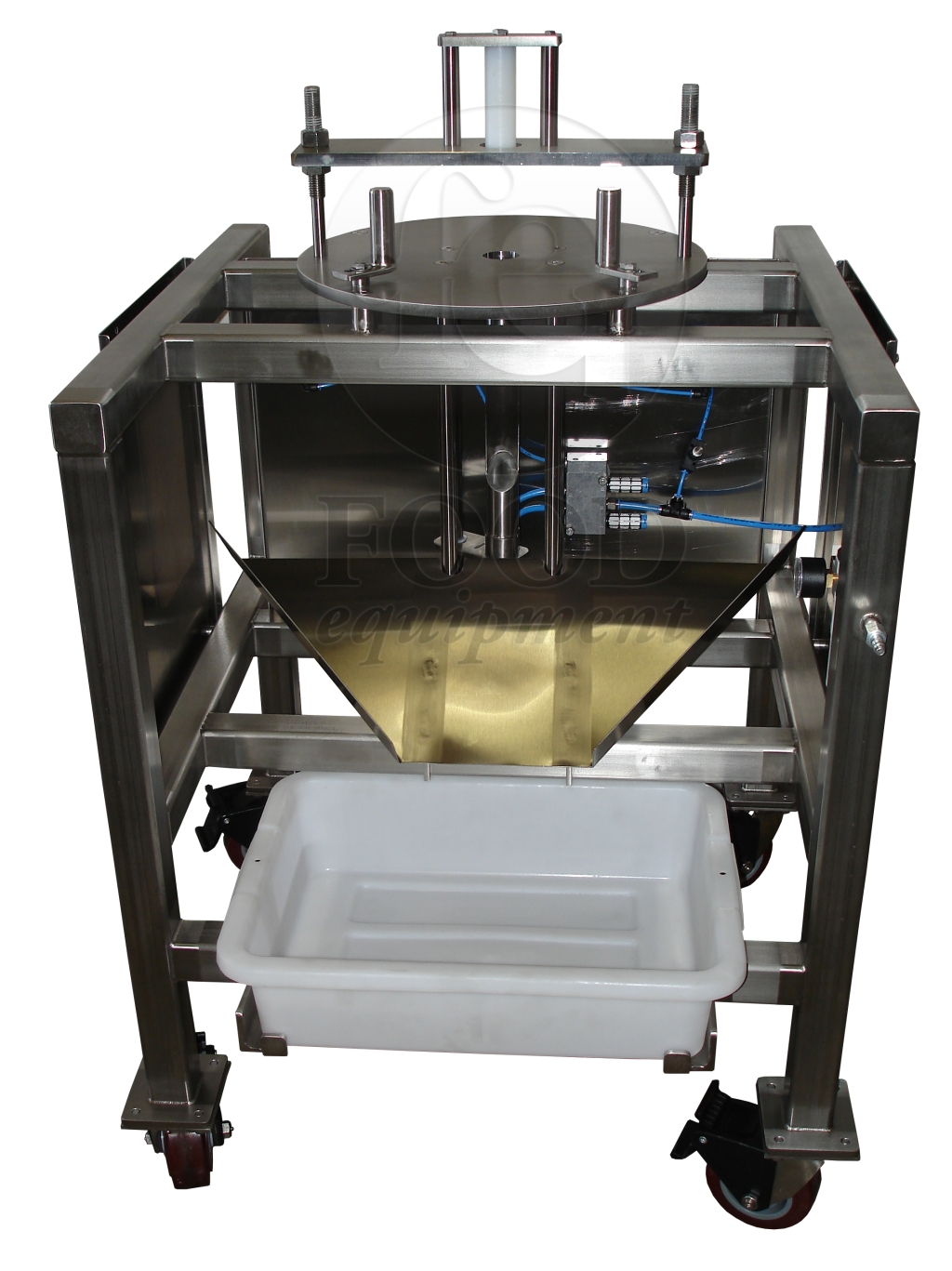

Modeled within the FEI500 Series, the FEI510 uses vertical motion to remove the core from the center of cheese wheels. Contrary to many of our other cutters that move the cheese through the harp, the FEI510 moves the harp (or core cutting device in this instance) through the cheese. The unit is constructed similar to all of our Food Equipment by utilizing stainless steel and UHMW components.

The quick disassembly of the stainless steel construction allows for easy and thorough cleanup.

The FEI510 has been designed to work in collaboration with the FEI500. Cheese wheels that are found to be unstable and crumble when using the Spike Harp Toolset tend to blow-out or fracture during the cut. The hard density of these types of cheese are unable to withstand the displacement of the leading spike and following wires. The FEI510 has been designed to alleviate this condition by removing the center of the wheel (called the core). The unit is setup to allow the cheese wheel to be perfectly centered before the core is removed, which increases the quality of the final product by generating consistent cuts per wedge.

This platform can benefit any solution where the cutting device passes through the product.

Specifications:

- Recommend Supply Air: 80-90 PSI

Leave a Reply