Project Lead The Way (PLTW)

PLTW’s mission is to ensure that America succeeds in the increasingly high-tech and high-skill global economy, by partnering with middle schools and high schools to prepare students to become the most innovative and productive in the world. [1]

Jim Faith, a PLTW Adviser, was not satisfied with the originally proposed bench-top type milling machine planned for purchase and installation at the Monroe High School. In collaboration with PLTW Instructors, Dan Saunders and Ed Neumann, Jim began conversations with Haas (a brand of milling machine used at Faith Engineering) to provide a more cost-effective solution that would allow students to solve ‘real-time’ problems by producing solutions on the CNC mill instead of merely simulating them on the bench-top type milling machine. In the end, the Monroe HS purchased the Haas machine for less than the bench-top machine.

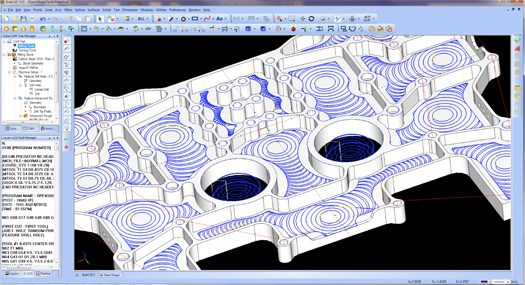

BobCAD-CAM — Complex Part

This Haas machine is a computer numerically controlled (CNC) mill, meaning the machine’s computer interprets lines of logic (called G-Codes) as statements which specify positions, speeds, moves and others functions such as when to enable/disable the coolant spray. Writing the G-Codes required for a simple part by-hand may prove not too difficult, but it is extremely difficult (if not impossible) to do for complex parts. BobCAD-CAM, the same software used at Faith Engineering, is now also used at the high school.

This software allows students to semi-automate the creation of the G-Code by importing the part’s Computer Aided Design (CAD) files. Two of Faith Engineering’s CNC machinists (Jeremy Cairy and Jeremy Gokey) have assisted with the new equipment installation, software training and continual support. Additional software licenses for BobCAD-CAM enable more students the ability to create jobs off-line and simulate the tool paths in a 3D environment before running the job on the real machine.

The industry is desperate for machinists, fabricators and other trade positions. The new equipment targets both the future college students (such as a Mechanical Engineer) and trade-school students (such as a Machinist) by peaking their interests to complete their schooling by being more employable right out of school. Helping educate our future generations is one way Faith Engineering gives back to our great community.

This week’s Friday Focus . . . . . . . . . Jim Faith

Friday Focus is a weekly news article created by the high school which recently nominated Jim Faith for his efforts regarding the new Mill.

A thoughtful email from the High School Principal read;

This week’s recognition goes to Jim Faith, he owns Faith Engineering in Monroe (although they are building a beautiful building north of town on Hwy. 69). Jim is also the father of Joel Faith and the husband of Terry Faith. Jim was nominated by Dan Saunders, and in his nomination he wrote:

I would like to nominate Jim Faith for this week’s Friday Focus. His continued support of the Technology & Engineering program at MHS is above and beyond what we expected. He has been instrumental in our advisory team which lead us down the correct path in the final sequence of PLTW courses. In just the past month alone, he has donated three pallets of steel, $3,000 dollars towards the new Haas CNC mill, 8 tool holders, a barrel of coolant and a pump. He was also instrumental in having the CNC mill delivered to his new facility for uncrating, rigging and re-rigging for the move into our shop, and arranging the final delivery to the high school. After this special rigging, one semi to bring the forklift and another truck and trailer bringing the machine, the CNC mill was carefully put into place last Friday after school. You don’t just have a $25,000 dollar machine delivered on a semi that weighs over 2 tons and unload it by hand! Jim has also made both of his CNC machinists available for technical support as needed (to the benefit of our program, both of them are former MHS students who attended my classes). One of them, Jeremy Cairy, spent Saturday morning with Jim and I as we did the final leveling, coolant pump installation and prepping the machine for the required factory technician to come and do the final set-up and machine verification. Jim made this all happen during an incredibly busy time personally and professionally, while moving his entire manufacturing and engineering facility to a new location and becoming a new host father to a foreign exchange student. He came up with amazingly abundant time and resources to help out and support us here at MHS. My hat is off to Jim for all of his help this fall and his continued support for the Technology & Engineering department.

This generous gift, and the skills it will allow our students to learn, will benefit our students and our community for years to come. This is just one example of how strong community partnerships can provide so much for our students if we let businesses and individuals into our schools and listen to what they have to share with us. Mr. Faith is passionate about the work that is done by his company; but he is equally dedicated to continuing that legacy beyond the walls of his business.

Thank you Mr. Faith for all you have done for our students and school community. Words can hardly express how grateful we are!! — Rick Waski, Principal, Monroe HS

Leave a Reply