Plastic injection molded combs are assembled to identification plates using rivets. A 6-axis robot arm is utilized for loading the plates. All parts are inspected before and after assembly to ensure a high quality product. The entire system sits on a single common structure making it easy to relocate.

Tag Archive: assembly

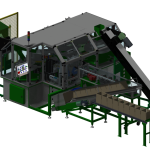

Multi-Station Assembly & Inspection System

This system assembles the Gap Compensating Nut Assembly at a rate of 30+ parts per minute, accomplished by rotary motion using an indexing drive. All finished part assemblies are inspected by Cognex cameras. Good part assemblies are deposited into shipping boxes ready to be sealed and labelled, while Bad part assemblies are sorted into totes based on their defect(s).