Need to reduce 40# blocks of cheese quickly? Our FEI700 is a semi-automatic 2-way horizontal cutter, designed to WDA Standards for direct washdown operations.

Category Archive: Divisions

Floor Model Pneumatic Pail Lidder

The Floor Model Pneumatic Pail Lidder is a self-contained, semi-automatic, mobile system that snaps plastic lids onto pails. Designed to be easy to operate, transport, and clean. The lidding machine supports various pail sizes and lid diameters via tool-less adjustments. The equipment is powered via compressed air only — as to not require the use …

FEI301 Reducing Table Cutter

The FEI301 Reducing Table Cutter is the ideal industrial cutter to handle large cheese blocks which require cuts in a single direction.

Two (2) FEI602 Two-Way Cutters (located on each side of the FEI301’s table) are designed to handle small rectangular cheese blocks which require cuts in two directions.

FEI620 Hydraulic Cheese Cutter

The FEI620 is a self-contained hydraulic cheese cutter, capable of exerting more than 4,900 pounds of force.

The interchangeable harp sets allow for a quick and easy change-over between the various sizes and shapes.

Two-hand touch control buttons ensure the operators hands are clear of danger when cutting and provide the operator illuminated feedback regarding the system status and any detected faults.

Accumulation Conveyor

The Accumulation Conveyor provides operators a steady supply of product to package by continually recirculating the product. The conveyor belts can be driven in either direction and at individual variable speeds to optimize for product size and the rate of production. Manufactured of 304 Stainless Steel & Food Safe plastics, designed & assembled to WDA …

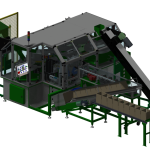

Comb Assembly & Inspection Machine

Plastic injection molded combs are assembled to identification plates using rivets. A 6-axis robot arm is utilized for loading the plates. All parts are inspected before and after assembly to ensure a high quality product. The entire system sits on a single common structure making it easy to relocate.

Multi-Station Assembly & Inspection System

This system assembles the Gap Compensating Nut Assembly at a rate of 30+ parts per minute, accomplished by rotary motion using an indexing drive. All finished part assemblies are inspected by Cognex cameras. Good part assemblies are deposited into shipping boxes ready to be sealed and labelled, while Bad part assemblies are sorted into totes based on their defect(s).

Pail Lid Applicator

The Pail Lid Applicator, also called a Pail Lidder, applies lids to each pail prior to sealing the lid as they ride along a conveyor. Various sizes of round buckets/lids; 2, 4 & 5 gallon (with other sizes available) are able to run on the same equipment with a 5 minute change-over between different products.

Manufactured of 304 Stainless Steel & Food Safe plastics, designed & assembled to WDA Standards — this machine is ready for direct washdown operations.