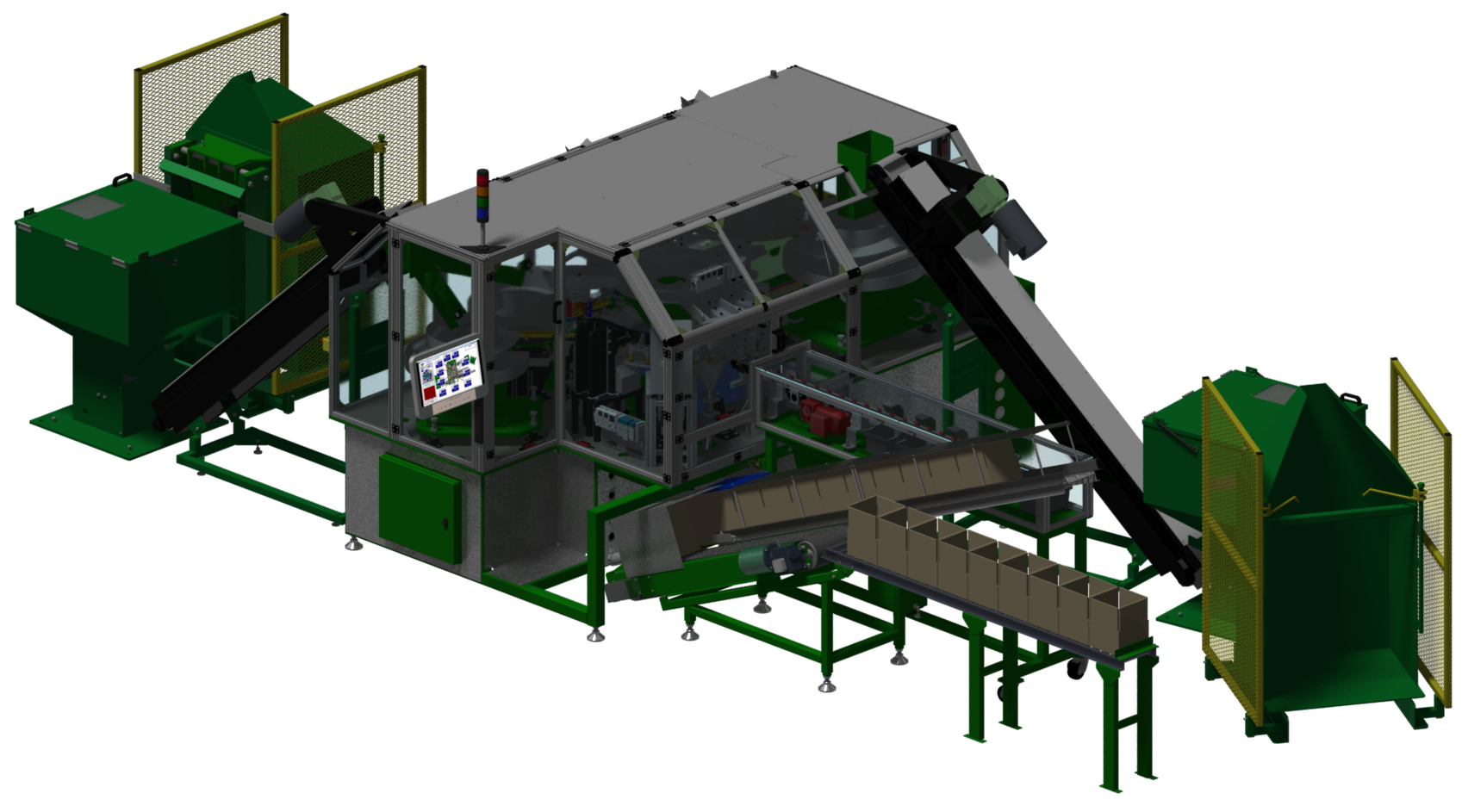

Bulk feed systems for the larger components reduce loading times and quantities.

The large main (and three smaller) enclosures protect the UL Certified electrical backpanels from the environmental factors within the production facility (ie. oil, dust, etc). The 13 guard doors provide easy and safe access into the machine; automatically switching the internal lights on and off to ease maintenance.

The 550+ Alarms makes discovering, diagnosing & resolving issues quick — keeping the machine producing.

A collection of top of the line components, primarily Allen-Bradley, form a large network of intelligent devices; minimizing electrical and software troubleshooting by reducing the amount of wire terminations. Pneumatic runs are kept short by placing Ethernet/IP valve bank manifolds local to their use. Various levels of permissions allow the administrator to customize each user’s access and responsibilities. The optional remote pendant allows maintenance to debug each individual station, capable of stepping forward and backward through the routines.

Capabilities:

The capabilities of this equipment are designed to meet, if not exceed, a set of custom requirements based on the needs of our customer. Our engineers are more than happy to customize a machine to your requirements.

- Bulk infeed handling of large components

- Torque Testing; Fine tune and validate the torque applied of threaded parts

- Rabbit Testing; Fine tune and validate the vision inspection of parts

Specifications:

- Footprint: 15 ft Long x 31 ft Deep

- Minimal Requirements

- Supply Air: 100 PSI @ 25 SCFM

- Power: 380 ~ 480 VAC, 3-phase @ 100 Amps

Approvals/Certifications:

Leave a Reply