Economically cut large cheese blocks in damp, corrosive environments.

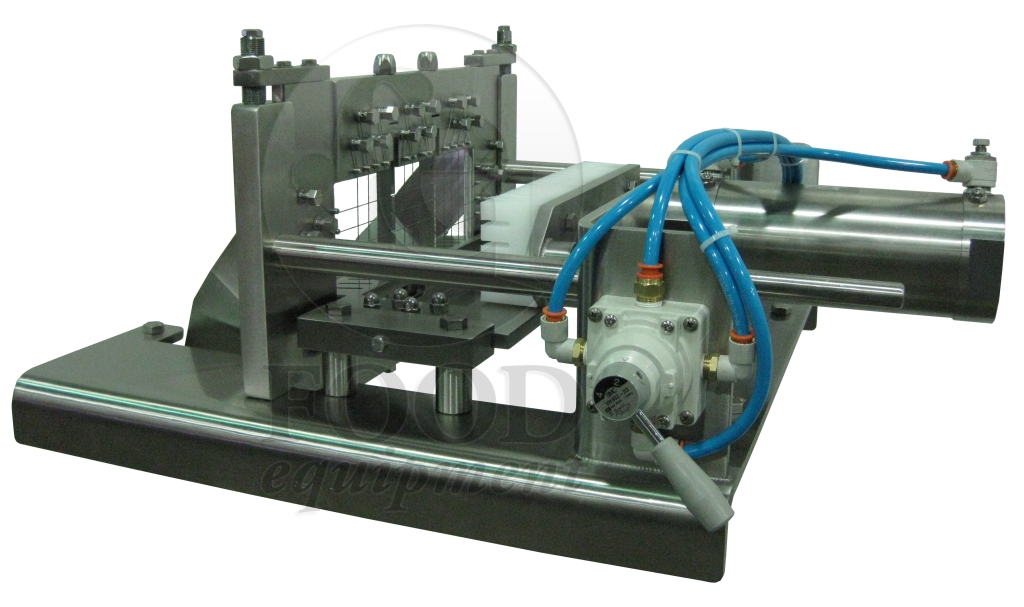

The FEI500 Series utilizes pneumatically-powered controls to avoid the need for electricity in a wet environment. The all stainless steel and plastic construction removes corrosion from the scenario. The industrial 500 Series cheese cutter consists of a vertical, single-push process set upon a modular platform which allows for additional options, such as the Cuber Attachment.

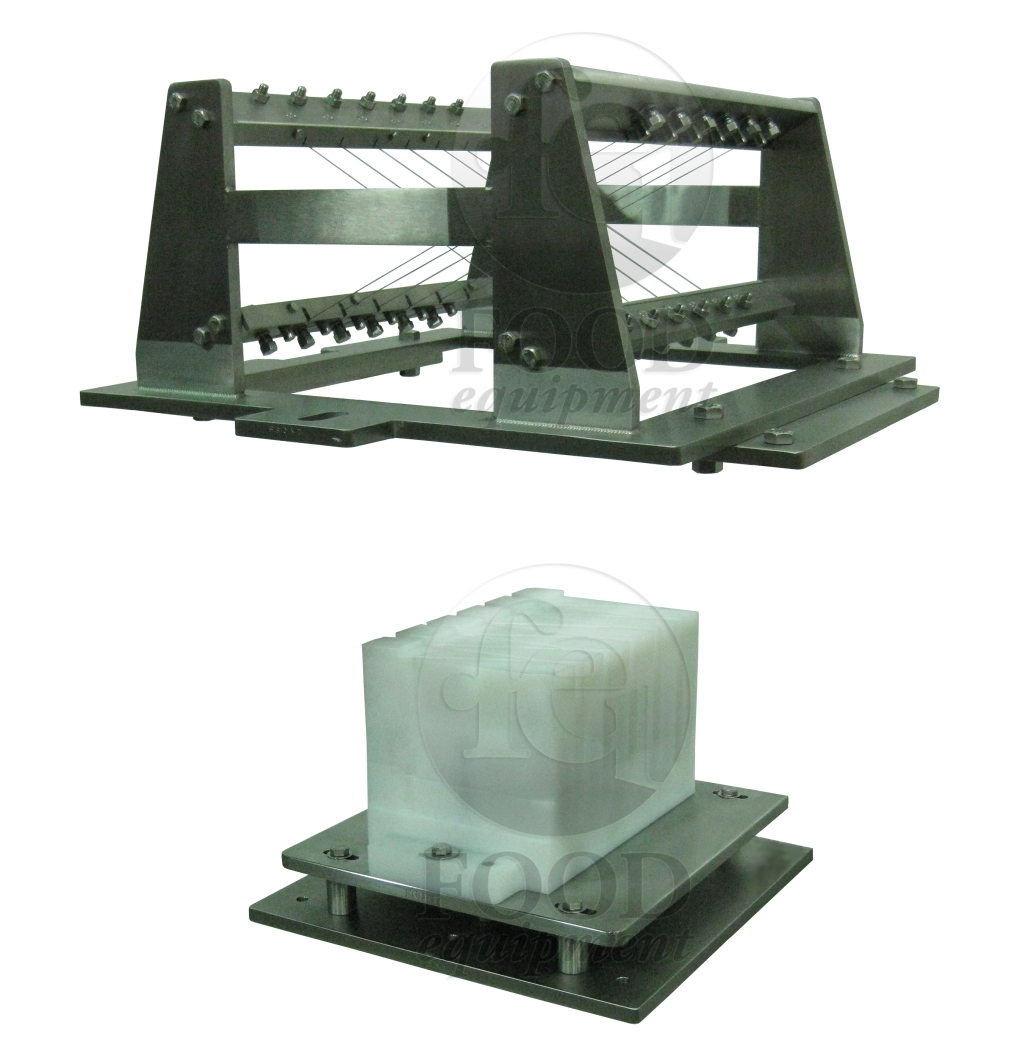

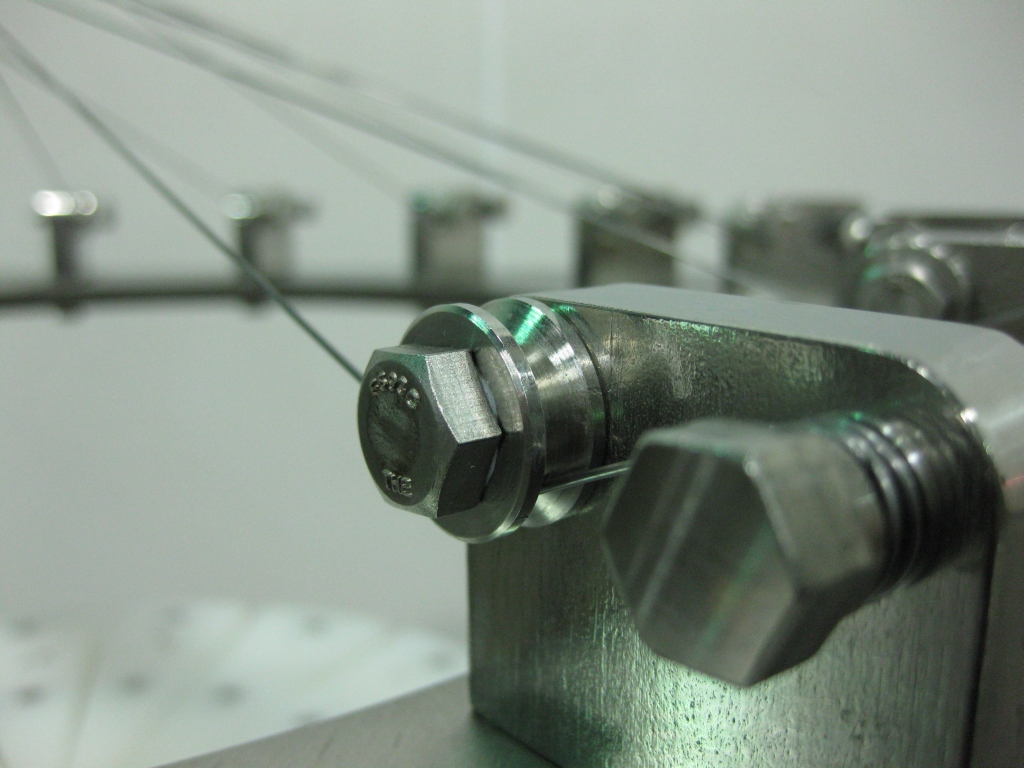

The unit illustrated has a harp designed to cut round cheese blocks (also called wheels) into equal sized pie-shaped pieces. The round blocks of product (called wheels) are pushed vertically through angled wires strung through a center spear. The harps are set up either for a single through-push or for a delay through-push, in which the next piece carries out the cut on the previous one. The FEI500 also features a system for cutting cheese into rectangular blocks using traditional style harps mounted in quick-change slides for easy cleaning. The optional Cuber Attachment allows for cubing of product.

To allow for better analysis of production yields, the unit tracks the amount of cuts that have occurred on a counter since the last time the counter has been reset. The completely pneumatically-powered unit also includes an air supply PSI indicator.

This cutter can be quickly and easily disassembled for cleaning. They are sturdily constructed of washdown materials.

Options

The harps which slice the cheese into various dimensions can be custom tailored to your needs. The harps use our standard quick-change technology, allowing for additional cut dimensions by different harps.

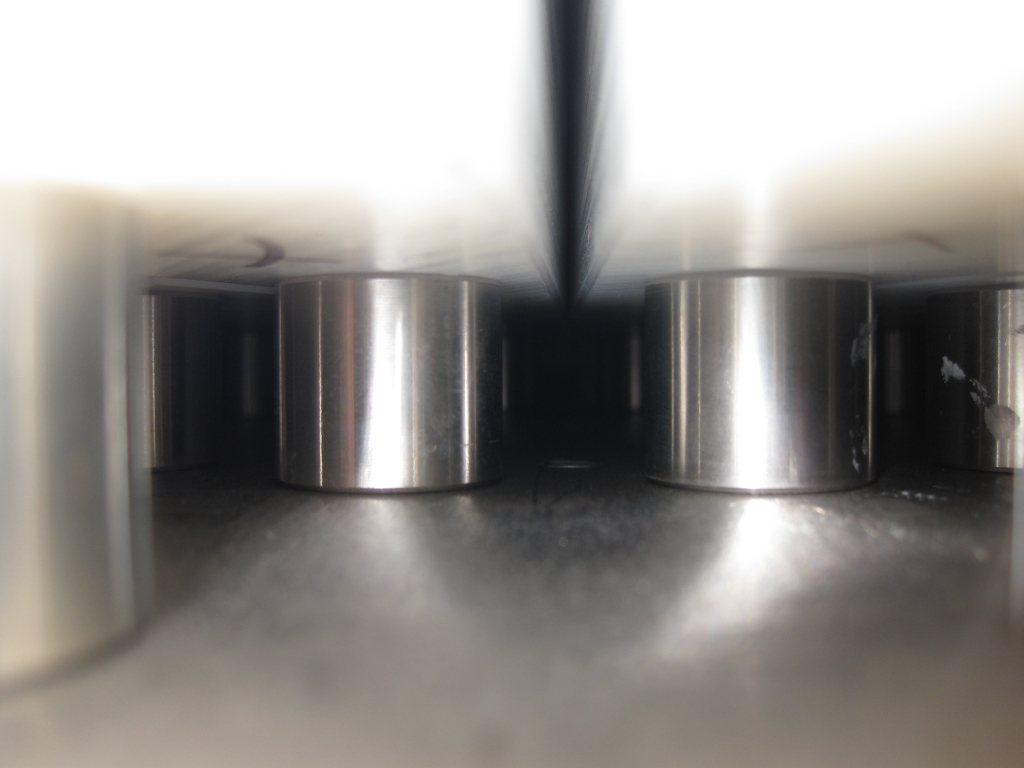

The Cuber Attachment adds a horizontal stroke used for cubing product. The smallest cubed dimension this attachment generates is 3/8″. All additional hardware associated with the Cuber Attachment can be disassembled with two wrenches. Cubing processes roughly 2-1/2 blocks of product per minute (depending on the operator).

Specifications

- Base unit (w/o harp) dimensions: 25-1/4″ L x 28-1/4 W x 53″ H

- Recommended supply air: 100 PSI

Leave a Reply