Two Cuts Above The Rest

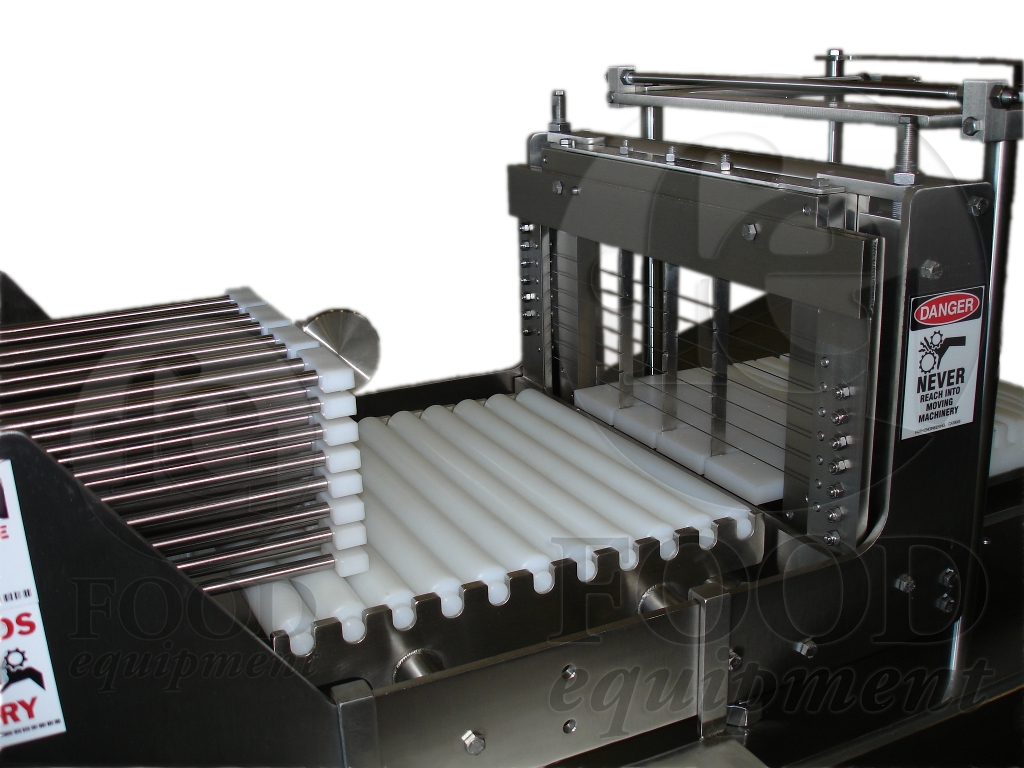

The FEI 610 Series line of cheese cutters has combined the best features of the FEI400 Series & FEI500 Series to deliver multiple cuts on the same product. Additionally implemented from these Series’ is a modular design to provide an almost endless platform for possibilities. The horizontal cut pushes the product first through a quick-change wire harp, then utilizing a ‘piggy back’ design the product is pushed through a series of blades that assists with the consistency of such a lengthy cut. Once activated by dual palm switches, the product is then pushed vertically through the final quick-change wire harp. The horizontal and vertical cutting processes can work independently and all harps can be changed out providing a larger range of customized cutting choices.

This cutter can be quickly and easily disassembled for cleaning, built of sturdily constructed washdown materials.

The FEI610 Series industrial cutter provides a solid platform to expand upon in the event larger product sizes are required. Round product (sized up to 14″ in diameter and 8-1/2″ tall) is commonly first horizontally cut in half, then cut vertically by a 32-piece wedge harp. Another common use for the round product (also called a daisy or wheel) is to skip the horizontal cutting and only use the vertical wedge cutting. Rectangular product (sized up to 11″ wide by 14″ long by 8″ tall, 40# block) is commonly horizontally cut producing multiple large rectangular pieces which are then vertically cut into proportionately long sizes.

This equipment is primarily constructed of stainless steel components along with various UHMW items to provide a long lasting and rust free solution.

The equipment can operate in a semi-automatic capacity by operating the cutting once a button press or palm-switches has been detected. It also has a manual mode which allows the operator to manually control the cutting stroke for cleanup purposes.

Leave a Reply